The Truth on Thread Count

October 7th 2015

Does a Higher Thread Count, Denote Better Quality?

When determining the quality of a linen sheet, the thread count only accounts for 1/10th of the finished fabric quality. To answer the question, it "depends." As TruthAboutThreadCount.com states, "Thread count is not an indicator of the quality of fabric, rather a description of what the fabric should feel like, and an indication of how tightly the fabric has been woven." Throughout this article, we will talk about what other factors affect the quality of commercial linens and how to avoid the common pitfalls of ordering linens.A Closer Look at the Meaning of Thread Count

Thread count refers to the number of threads woven into one square inch of fabric. There are many different techniques for weaving such as plain weave, percale, and sateen (see below). The thread count is based on the number of threads woven horizontally and vertically. It is hard to put a number on the maximum number of threads that can be woven into one square inch because there is currently no manufacturing regulation or guideline for how to count threads. Pat Slaven, a textile expert from Consumer Reports states, "Spending money on sheets that are more than 400 count is not necessary." Sheet thread count can be compared to SPF lotion. After the maximum thread count or SPF is reached, the rest is a marketing ploy.Factors Affecting the Quality of Sheets

Cotton Species

There are four main types of cotton grown throughout the world, and each species of cotton has it's own size, feel, and quality.- Gossypium barbadense

- Native to South America (8% of world production)

- Highest Quality, Longest Cotton Fiber

- Other names include: Egyptian, Pima, Giza 45, Supima, Suvin, Barakat, Sea Island

- Gossypium hirsutum

- Native to the Caribbean, Central America, Mexico, and Florida (90% of world production)

- Comes in two forms: Short and Long Staple American Upland

- Most common type of cotton

- Gossypium arboreum

- Native to India and Pakistan (1% of world production)

- Known as Tree Cotton, features shorter fibers

- Shorter fibers lead to lower quality

- Gossypium herbaceum

- Native to Sub-Saharan Africa and the Arabian Peninsula (1% of world production)

- Known as Levant Cotton

- Levant seeds are used in many medical situations

Click to View Entire Hotel Linen Collection![/caption]

Click to View Entire Hotel Linen Collection![/caption]

Length of Fiber

The length of fiber is determined by the genetics of the cotton. Once the cotton blooms, it generally takes 21 days or longer for the cotton to fully mature. Cotton is most preferred when it is strong and at its peak length. The longer the fiber, the better the cotton can be spun into yarns, resulting in a smoother feeling fabric.Quality and Grade of Fiber

Within each of the four categories of cotton, the quality of cotton can vary from harvest to harvest. The following are specifications farmers and manufacturers look for when grading the quality of cotton.- Color

- If cotton isn't pure white, additional chemicals are needed to enhance the cotton, damaging the strength of the cotton fibers.

- Debris

- Natural debris that nestles inside the cotton needs to be taken out before the weaving process. This process weaknesses the fibers and leaves weak spots or holes within the cotton.

- Maturity

- The longer the cotton is left to grow, the more durable the fibers become.

- Mixing

- There are no regulations for mixing. For example, sheets that are advertised as Egyptian cotton may only contain 1-5% of actual Egyptian cotton. However, benefits with mixing can be seen when cotton is mixed with polyester to give sheets the durability a hotel needs, with the softness a customer wants.

Cotton often contains debris, which affects quality.[/caption]

Cotton often contains debris, which affects quality.[/caption]

Yarn Thickness

Manufacturers are able to produce sheets with higher thread counts when their cotton selection features long, smooth fibers. If a bunch of small fibers are needed to spin together a yarn, the fabric may have a high thread count, but the material will be heavy and bulky. A good indicator of the quality of your sheets is how light and soft they are. High thread count sheets that are light are made of single long strands of fiber, rather than multiple short strands.Plied Yarn

Plied Yarn is when fabric is weaved using multiple weaker yarns to form a single strong yarn. This allows for the weaker small fibers to be used together, which results in a higher thread count, but a reduction in quality. This is where you get 800 count sheets that show no improvement in quality versus a 200 count sheet.Weave Type

- Plain Weave

- The traditional method of one yarn over, one yarn under.

- Percale

- Many of our sheets and linens feature the percale weave. This method involves the same method as the plain weave, but with higher quality cotton fibers. Percale features a flatter, matte finish compared to other weave types.

- Sateen

- Using a four over, and one yarn under method, the sateen weave produces a sheen and soft feel.

Country of Origin

Historically, the best cotton in the world originates in Egypt. Egyptian cotton gained popularity because of it's long staple cotton fibers. Today, what consumers refer to as "Egyptian cotton" is grown worldwide. The demand and price of Egyptian cotton leaves it undesirable for most commercial use, however technology and science has allowed countries such as China, India, and Pakistan to produce marketable sheets from lower grade cotton. [caption id="attachment_638" align="aligncenter" width="660"] Credit: Kimberly Vardeman[/caption]

Credit: Kimberly Vardeman[/caption]

Fabric Finish

The last factor that can affect the quality of sheets is the type of fabric finish used after the fabric has been fully woven. Finishes help to eliminate wrinkles, maintain smoothness, and preserve color. Below are two common finishes used.- Easy Care

- Easy care linens are important for the hospitality industry. This finishing touch improves crease recovery and increases the likelihood of continuous smooth drying.

- Softener

- Used to stabilize the structure of the fabric, softener is used to give the consumer that "ahhh" moment of softness. Based on the yarn and weave type used, sheets will vary in softness.

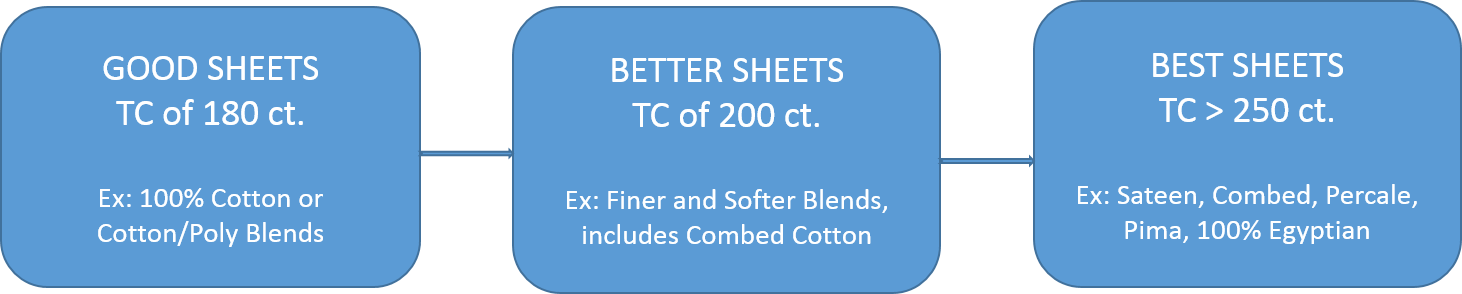

The Truth on Thread Count

I hope you have enjoyed reading about cotton and how multiple factors affect the quality of your hotel's sheets and linens. While thread count is a good starting point for determining how soft the sheet should feel, it isn't the sole indicator of quality. Make sure to look for words such as combed, percale, sateen weave, pima, and 100% Egyptian when looking for more luxurious sheets. If you're looking for more economical sheets, plain weaved 100% cotton or cotton/poly blends will get the job done, at a manageable price. [caption id="attachment_656" align="aligncenter" width="660"] Click to View Larger[/caption]

Click to View Larger[/caption]